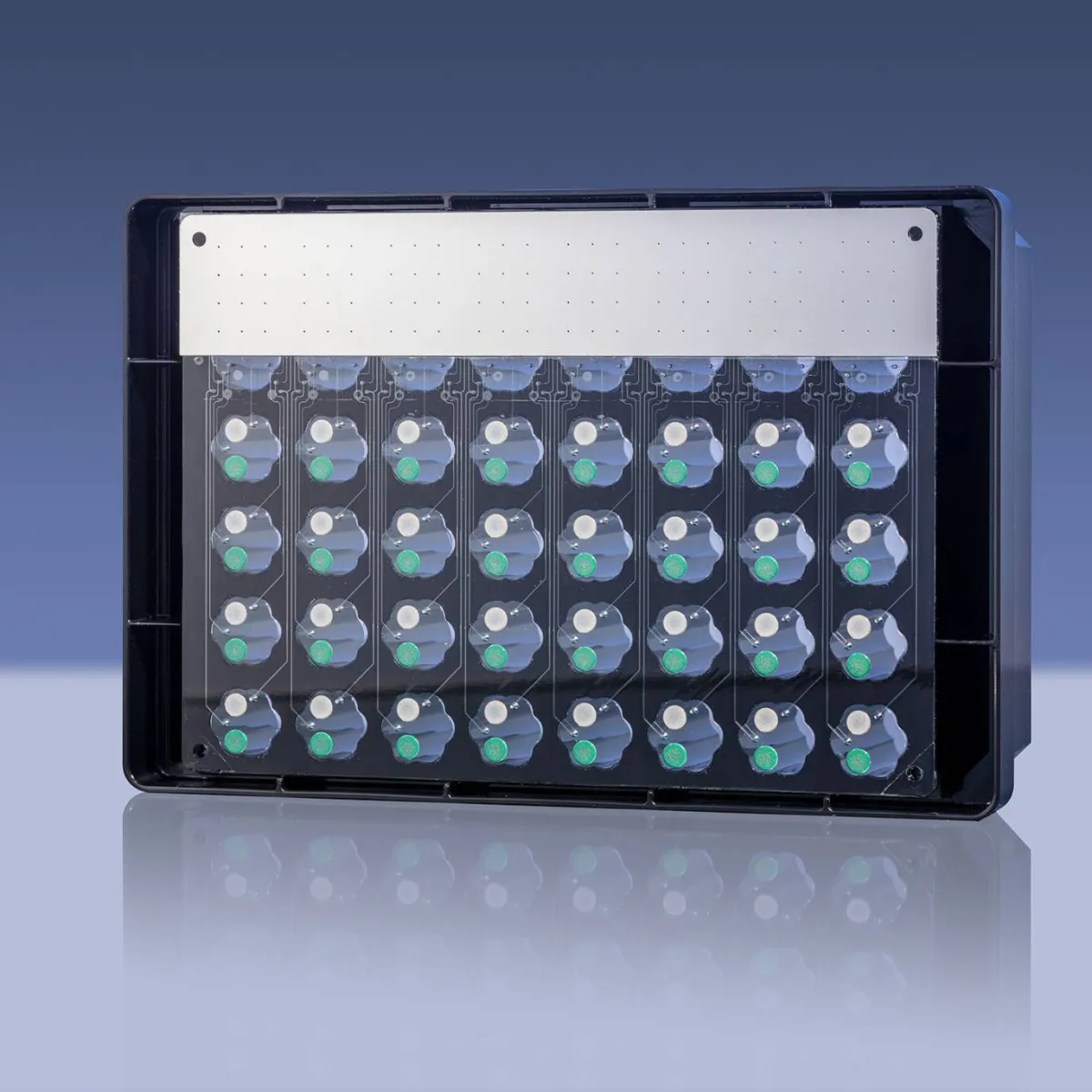

NextGen Microfluidic Microtiter Plate

Products

Information

The NextGen Microfluidic Microtiter Plates facilitate high-throughput screening

in up to 32 individually controllable cultivation wells. The proven technology of microscale feeding combined with non-invasive measurement of the most relevant fermentation parameters, e.g. biomass, as well as pH, DO and fluorescence, enables an industrially-tailored bioprocess development and its optimization. All 32 cultivation wells can be

controlled individually through microvalves and microfluidic channels allowing for high-precision pH control and feeding at a CV (coefficient of variation) of < 6% with regards to the pump rate*1. Overcome the limitations of static batch processes and screen within defined conditions for successful upscaling. The beta-irradiated, fully disposable, ready-to-use plate means no tubing and no liquid handling is required.

*1 Determined with a fluorescein-containing buffer at a constant pump rate of 5 μL/h.